production steps

the steps to perfection.

Many steps are required for the production of high-quality panels for tanks, silos and vessels. We at GLS Tanks attach equal importance to each individual processing step in order to satisfy our customers‘ high quality standards.

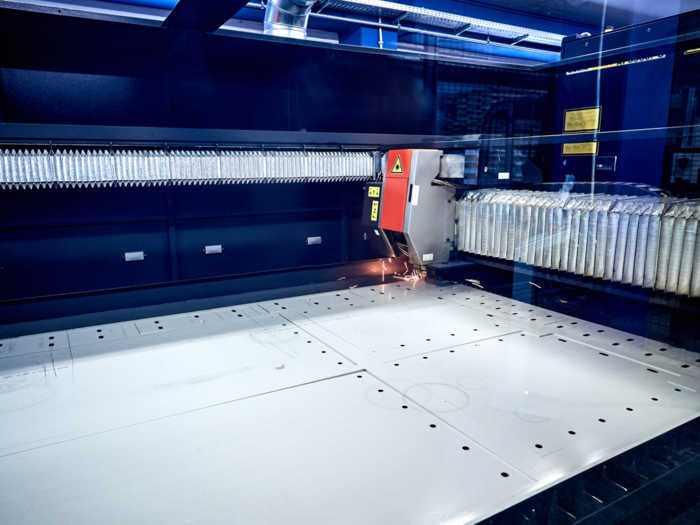

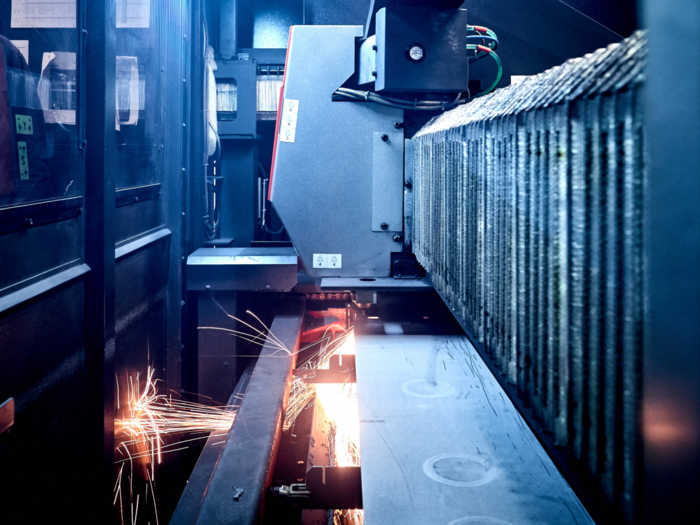

1. Laser:

The raw sheets are cut with our laser.

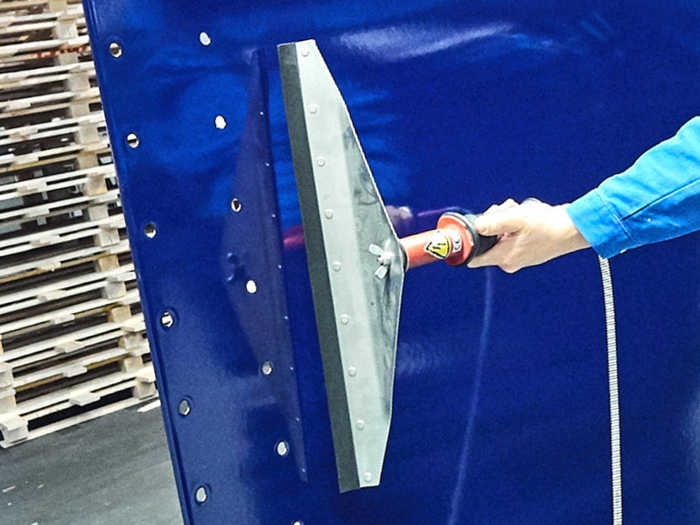

2. Deburring:

Depending on the customer's request, we can also round the edges of the sheets.

3. Brushing - Bending:

The sheets are brushed all over and prepared for the enamel process.

4. Powder:

The PUESTA process combines the powder with the raw sheets through an electrostatic process.

5. Enamel:

The powder and the raw sheet combine in our high-performance furnace at approx. 800°C, creating an absolutely corrosion-resistant surface.

6. Inspection:

After the furnace, the panel are subjected to a comprehensive pore inspection and a detailed visual inspection by our qualified employees.

7. Packaging:

Before the panels are packed, an edge protection is applied as a transport protection. Ready-packed, the panel packages are commissioned for specific projects.

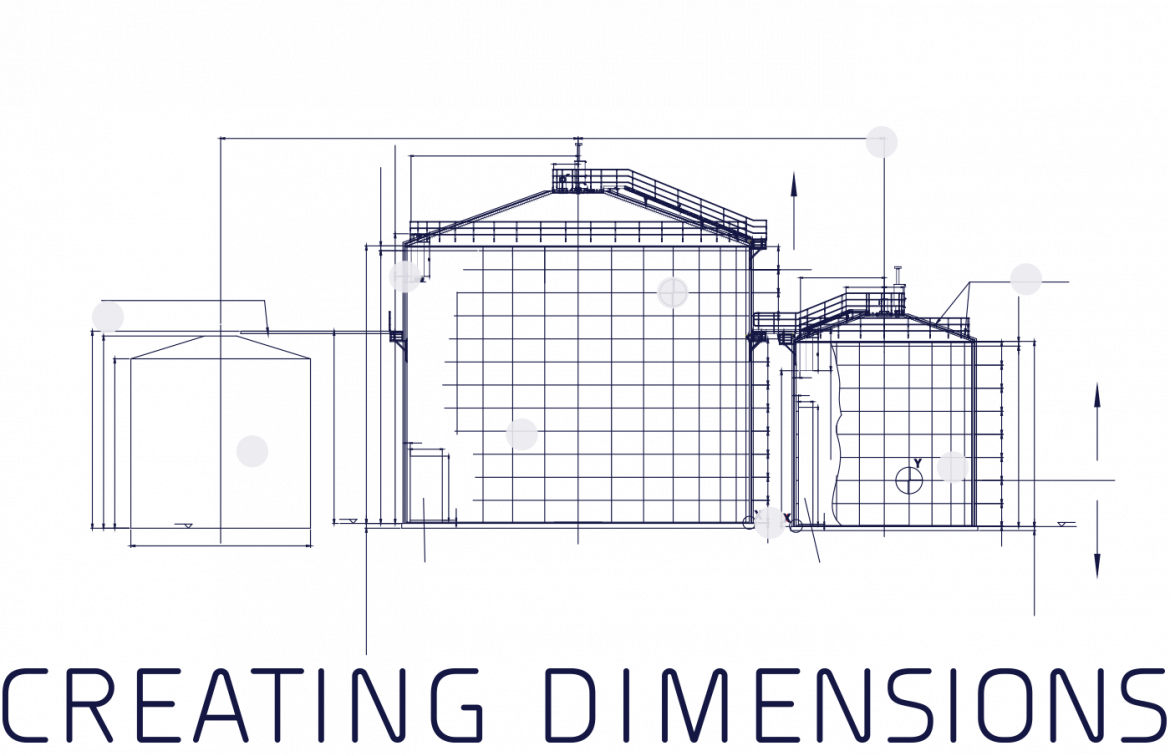

product designs

ENAMEL

Glass melted on steel offers best corrosion resistance and makes the product stable as well as elastic. GLS Tanks offers enamelling on S700 BASIC-, S700 PRO- and S700 PRIME-glass.

That's the process: The enamel powder is applied to the panels by electrostatic charging. In the furnace, the powder-coated panels are heated to approx. 800 °Celsius. The enamel powder melts in this process and forms a permanent connection to the metal surface. The resulting glass-like and extremely resilient enamel layer protects the entire steel surface permanently.

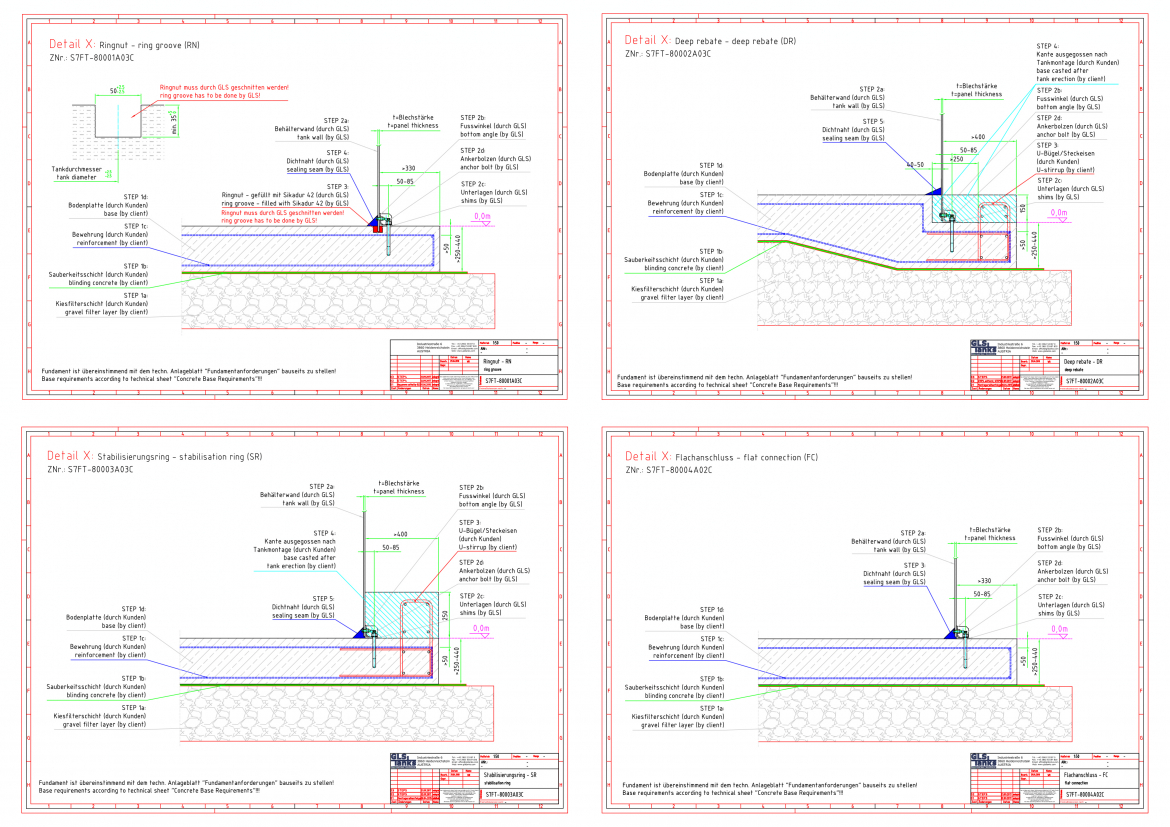

Foundation connection

The connection between the tank and the foundation is another important criterion. GLS Tanks offers four connection systems:

- Ring groove

- Stabilising ring

- Flat foundation

- Deep rebate

Edges

We apply an edge protection to the edges by default, which is particularly important for panels that have not been deburred. We conduct deburring on request, during which the panels will be rounded off at the edges to achieve continuous enamelling.

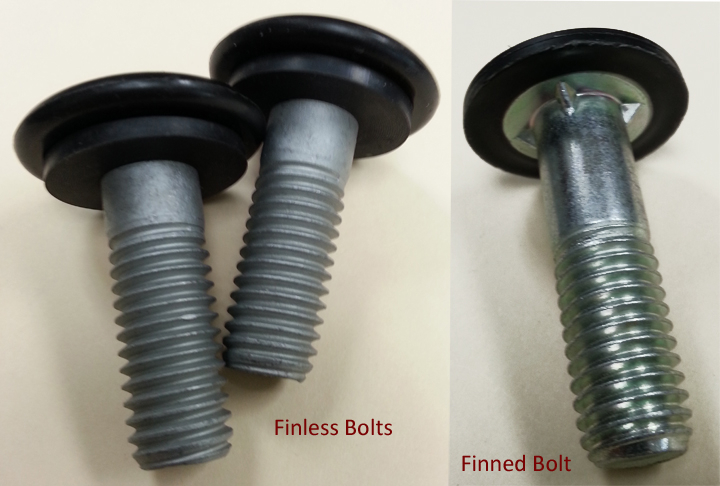

Bolting

The special bolts used for joining the panels together are an additional advantage. We provide three variants:

- Galvanised tank bolt

- Tank bolt A2 (1.4301)

- Tank bolt A4 (1.4571)

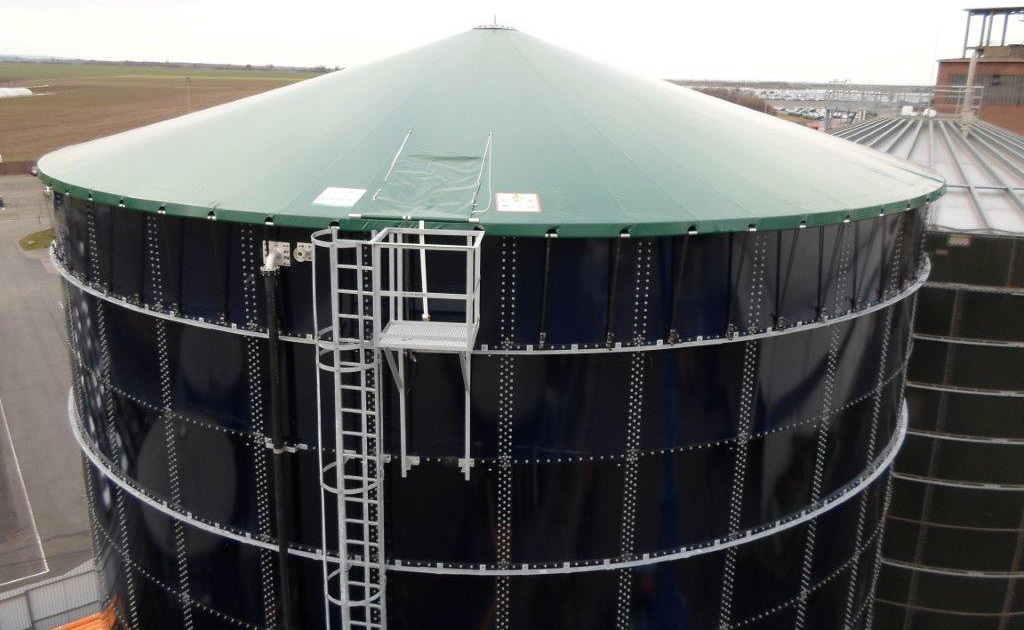

Further benefits of our tanks

High durability, temperature-resistant, easy assembly, low maintenance, swift disassembly, long service life, no special transport due to the system dimensions, extendable.

Further benefits of the enamel coating

shock-resistant, abrasion-resistant, scratch-resistant, dirt-repellent, hygienic surface, non-flammable

Environmental Protection

Our company is located in the region called “Waldviertel“, which can be characterized by unspoiled nature. Therefore, environmental protection as well as saving of resources are paramount to us.

Consequently, we have taken the following measures:

-

Our packaging material consists of 100% renewable and recyclable materials.

-

We supply excess heat from our enamel furnace to companies in our neighbourhood.

-

Modifications to the furnace enabled more energy efficiency.

These changes have resulted in a Co2 reduction of more than 40 tonnes a year.

-

As fluorocarbons significantly contribute to the greenhouse effect, we have considerably reduced their percentage in the enamelling process.

-

Nickel is proven to be carcinogenic and the most frequent trigger for contact allergies (see Directive 2004/107/EG). In order to protect both our staff and the environment, we at GLS Tanks do not use any toxic nickel and etching baths. Moreover, we exclusively use nickel-free enamel powder. Thus, we correspond with the latest environmental legislation of the European Union.

-

By optimizing the panel lengths, we have reduced the use of sealants (petroleum product).

-

We have significantly reduced our power consumption by installing special systems.

These measures correspond to savings of more than 10 tons of CO2 per year.

Accessories

Quality right down to the smallest detail.

Each product and every solution is only as good as the sum of its parts. Therefore, we at GLS Tanks also attach great importance to the supply of high-quality anciallary equipment. Therefore, we offer a wide range of ancillary equipment including custom-made solutions.

Roofs

Steel-enamel roof: In the default version, the roof inclination is approx. 20°. The roof carriers are installed on the outside of the roof. At the centre of the roof, they merge into the crown ring, at the container edge into the head angle.

-

Self-supported roof structure of hot-dip galvanised profiles

-

Enamelled roof panels below the steel structure installed with special stainless steel screws or hot-dip galvanised special bolts

Aluminum Dome: Compared with a carbon steel roof the aluminum dome is light-weighted, non-corrosive, easy in handling, simple and fast to install, at low costs and has a long life expectancy. These facts make an GLS Aluminum Dome a great investment and the right decision. Our Aluminum Domes are fast and easy for installation, provide absolute tightness and have excellent stability.

GLS flat roof: In the default version, the trapezoidal sheets are made of aluminium or zinc-plated/coated steel sheet with surrounding edge cover.

-

Self-supported substructure of hot-dip galvanised steel carriers with a diameter of up to 10 m possible

-

Accessories: roof hatch 600 mm x 600 mm, can be opened on the side

Double membrane roof: In the default version, the cover is made of a PVC-coated polyester fabric. It is UV-resilient and made of welded fabric lanes.

- Center support made of stainless steel (V4A)

- PES bands including stainless steel ratchets in V4A

- Incl. overpressure and vacuum protection for the gas side

- Pressure protection flap for air pressure protection

- Fan EX-protected

PVC-tarpaulin roof: In the default version, the roof inclination is approx. 17°. The cover comprises a PVC film with welded-on welding bands.

-

Welding bands are tensed at the tank wall with stainless steel ratchets

-

Central column in the middle supports the tarpaulin roof

Access

Ladders (standard design)

- Production according to EN 1090

- Material: S235 hot dip galvanized

- Back protection as of 2.5 m

Staircase incl. resting platform (standard design)

- Material: S235 hot dip galvanized

- Interim platforms at height distances of 3 m

- Width: 800 mm

Platforms (standard design)

- Material: V2A or V4A stained, S235 hot dip galvanized

- Standard length: 150 mm

- Designs: one-sided outside

Flanges & Hatches

Flanges (standard design)

- Production according to DIN 2576

- Pressure level: PN10

- Material: V2A or V4A stained, S235 hot dip galvanized, epoxy-coated

- Standard length: 150 mm

- Designs: one-sided, double-sided

Hatches (standard design)

- Material: V2A or V4A stained, S235 hot dip galvanized, epoxy-coated

- Standard length: 150 mm

- Designs: one-sided outside

Insulation

- Standard insulation: 100 mm with mineral fibre mats

- Standard: hot dip galvanized/coated steel-trapezoidal sheets

- Special: coated aluminium trapezoidal sheets

- 16 standard colours

- 37 special colours can be ordered (with 5 weeks' delivery time)

Mixer flange (standard design)

- Material: V2A or V4A stained, S235 hot dip galvanized

- Standard length: 150 mm

- Designs: one-sided outside

Safety Devices

High-/Low-Pressure Valve

Burst discs

Other components

Scraper Track

Level Indicator

Clearwater channel

Gasdome

Sludge efluent shaft

Funnel

Preparation for third party installations

Sight Glass

Railings (Standard Design)

- Production according to EN 1090

- Material: S235 hot dip galvanized

- Hand Rail, Guard Rail, Base Rail